Besides warranty maintenance of molds from our production, we have everything needed for potential mold modifications or their repair. Our technological equipment and know-how can remove a thorn from your side in situations where every minute counts.

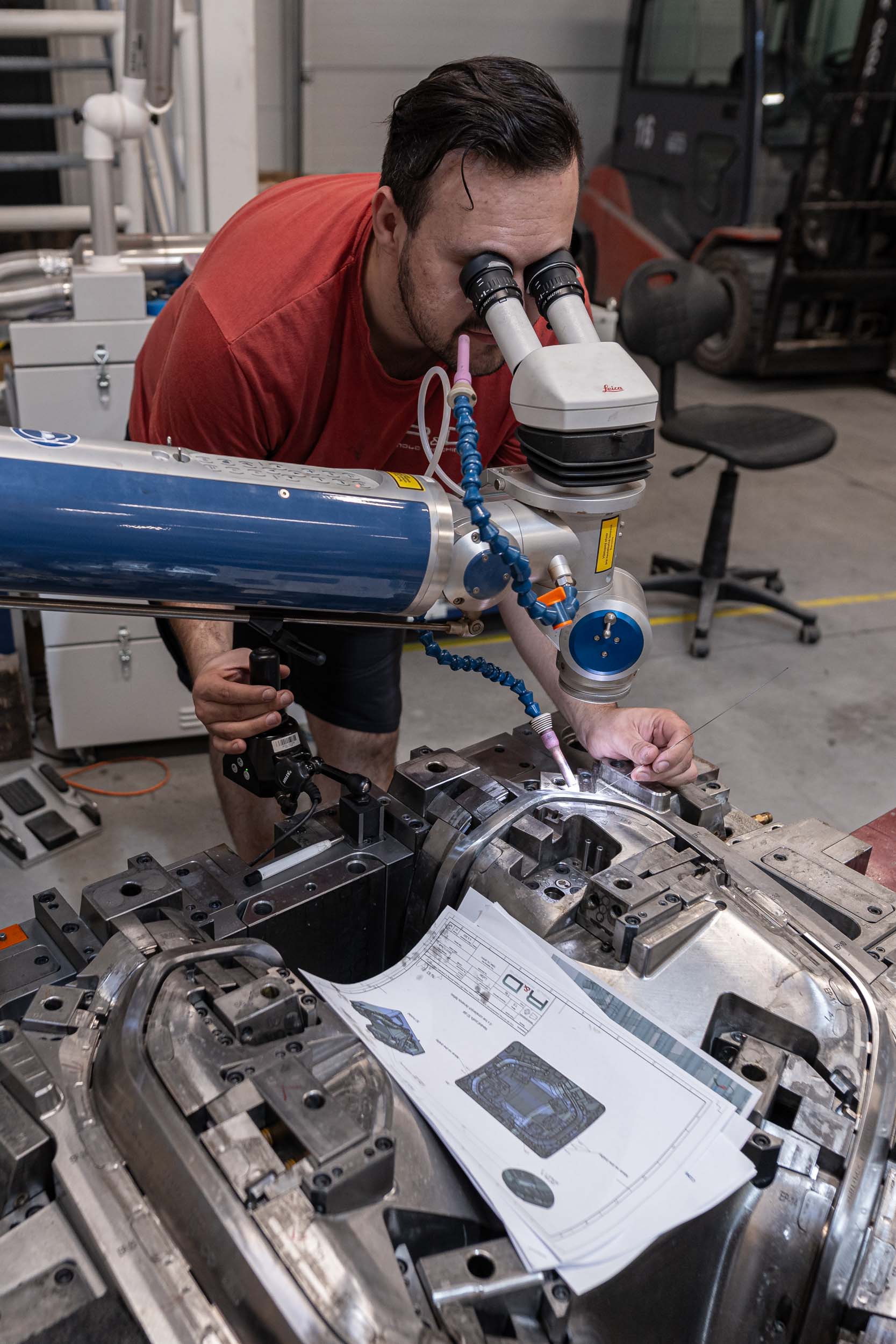

Maintenance is crucial for ensuring optimal production operation. Therefore, after a certain number of production cycles, we provide comprehensive maintenance and inspection of the mold. We perform maintenance on molds from our production within warranty terms and on molds and devices from other productions that require it due to wear. We manage the maintenance process with minimal interruptions to your production process.

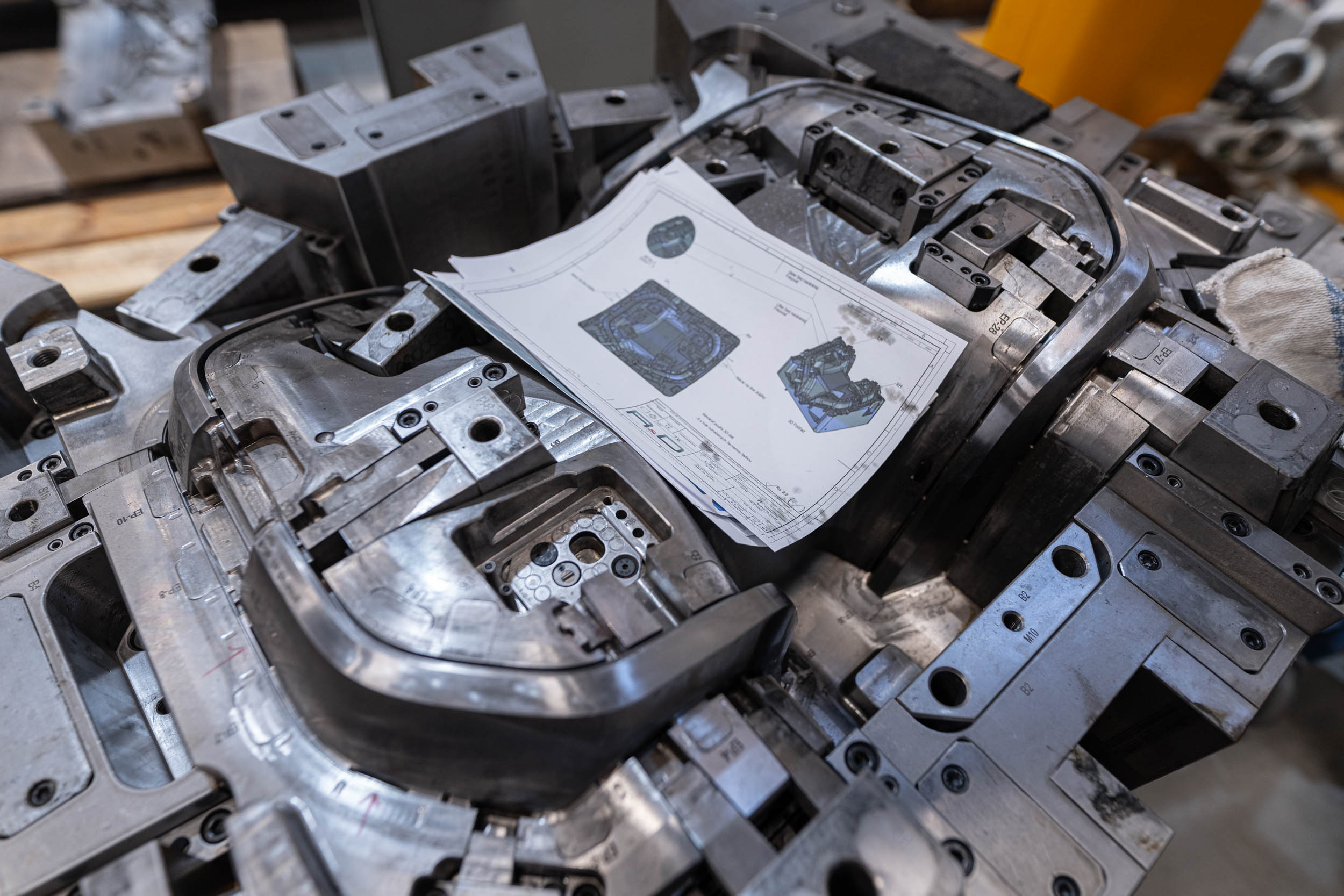

If your mold needs more work for plastics or composites production, we’ll modify it to ensure part production meets the required parameters. This need could include changing the counterpart, adjusting product parameters, or any other production change leading to unsatisfactory product qualities. Our experts will provide complete engineering services to make mold modification as efficient as possible without causing significant complications in your production plan. We modify molds and products from our production and molds from other manufacturers.

Initially, we must intervene in the data required for mold production. We will adjust all necessary information to introduce any new mold revisions. This step is essential for any further modification or repair of the mold.

For molds from other manufacturers, we verify the mold’s actual condition and parameters using reverse engineering approaches. We compare these with the provided documentation to ensure the problem isn’t due to discrepancies with the actual state.

Based on the designed changes, we modify the mold using the latest technologies, using new or modified parts, allowing the production of parts according to new requirements.

After agreeing with the client, we will provide control outputs of new parts from the modified mold to verify the achieved goal. We record all changes to the modified mold in the documentation and provide the necessary measuring protocols and 3D data.

Sometimes, situations require quick and immediate intervention. When production stops and minutes turn into hours, we have a backup plan. Our escalation team is ready to solve mold crashes as quickly as possible to minimize damages caused by production halts. Once we assess the condition and extent of the damage (e.g., due to stress, overload, unexpected accidents, etc.), we’ll find the most efficient solution to restore the mold with our experts and technological base.

An internal team of designers and programmers,

Utilizing SolidWorks for part and tool design,

Moldex3D for mold flow simulations,

SolidCAM software.

3-5-axis CNC milling (15 machines), max. part size 2600x1600x800mm,

6-axis CNC turning (2 machines), max. part size D500x700mm,

High-speed CNC machine with graphite electrode.

EDM cutting (2 machines), max. part size 1000x550x310mm,

EDM die sinker (3 machines), max. part size 1600x800x600mm.

Surface grinding machines,

Rotary part grinding.

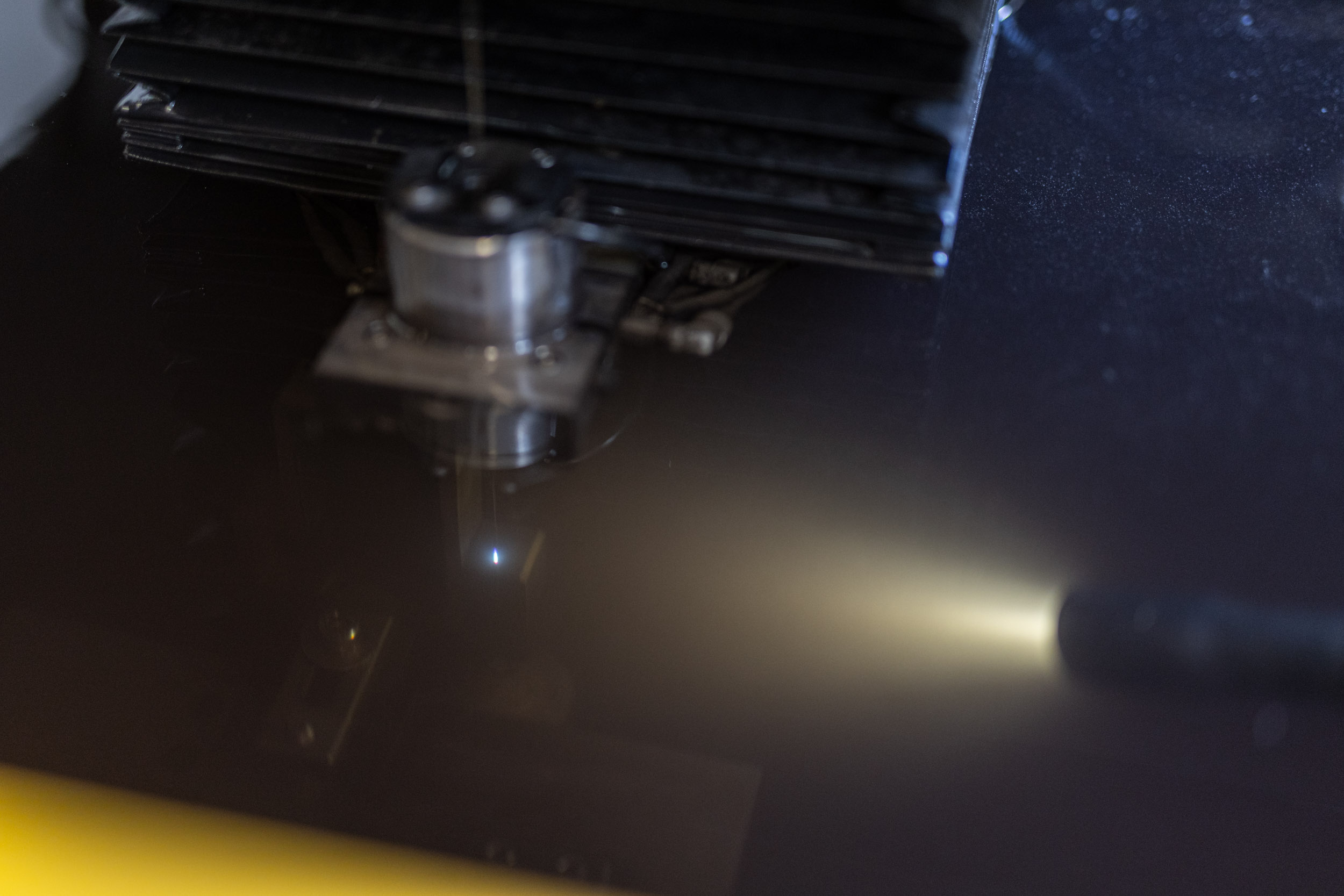

Capabilities for laser welding, marking, and engraving parts.

Machines up to 250t and maximum mold size 1.2×0.8m.

3D CMM machines (3 units), max. part size 1500x1000x800mm,

3D laser scanning (accuracy 0.008mm),

ISO 9001 and ISO 14001 certifications.

Quick repair and modification.

Measuring fixtures, painting fixtures, adhesive fixtures, and more.

We can ensure the production of prototype molds according to your requirements, for example, small-scale production, intermediate part production, pilot trial mold production, or verification of product parameters.

Our specialty is producing molds for composites. In a comprehensive range, we can cover the related services for carbon part mold production, sample creation from the mold, and even final production in cooperation with the R&D COMPOSITE division.

We provide production and related services for a wide range of products. Examples include tools, components and parts, devices, spare parts, robotics, or parts for the automotive and other industries.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-advertisement | 1 year | CookieYes sets this cookie to store the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-analytics | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Analytics” category. |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by the GDPR Cookie Consent plugin to record the user consent for the cookies in the category “Functional”. |

| cookielawinfo-checkbox-necessary | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to record the user consent for the cookies in the “Necessary” category. |

| cookielawinfo-checkbox-others | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Others”. |

| cookielawinfo-checkbox-performance | 11 months | Set by the GDPR Cookie Consent plugin, this cookie is used to store the user consent for cookies in the category “Performance”. |

| CookieLawInfoConsent | 1 year | CookieYes sets this cookie to record the default button state of the corresponding category and the status of CCPA. It works only in coordination with the primary cookie. |

| elementor | never | The website's WordPress theme uses this cookie. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| wpEmojiSettingsSupports | session | WordPress sets this cookie when a user interacts with emojis on a WordPress site. It helps determine if the user's browser can display emojis properly. |

| Cookie | Duration | Description |

|---|---|---|

| wp-wpml_current_language | session | WordPress multilingual plugin sets this cookie to store the current language/language settings. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 1 year 1 month 4 days | Google Analytics sets this cookie to calculate visitor, session and campaign data and track site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognise unique visitors. |

| _ga_* | 1 year 1 month 4 days | Google Analytics sets this cookie to store and count page views. |